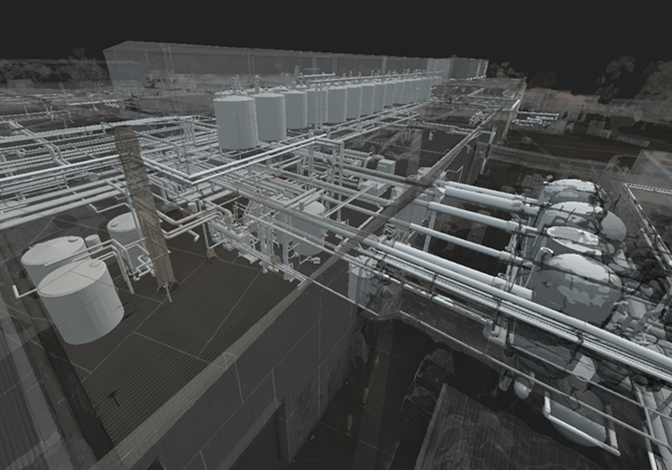

REVIT Modelling of Factory Pipes

High accuracy terrestrial laser scanning survey and scan-to-Revit modelling of ammonia piping to support upgrades

PROJECT OVERVIEW

A manufacturing plant required maintenance and upgrades to their ammonia piping. To support this, the asset owner required a high accuracy revit modelling of the plant and the intricate piping network, specifically the ammonia piping, for engineers to complete designs of upgrades.

Due to the complexity of the site, care needed to be taken to ensure a robust survey control was in place and a good understanding of the piping network.

Project Scope

DIOSPATIAL SOLUTION

Diospatial developed a high accuracy terrestrial laser scanning solution that utilized a robust network of survey control points.

First, a survey control was established throughout the plant using a series of laser scanning control targets and total station. Then the laser scanning technician completed a detail scan and capture of the entire plant and intricate network of piping using the Leica RTC360 terrestrial laser scanner.

The laser scanning point cloud was then processed to produce a colourised point cloud. The resulting registered point cloud was geolocated and exported in various file formats foe ease of use by a range of third party applications.

The point cloud was then used as part of a scan-to-Revit modelling workflow, with Diospatial’s expert modelers using Autodesk Revit to extract the ammonia piping elements and other important plant components. This produced the detailed Revit model that was then delivered to the client.

Several rounds of quality control were completed to ensure that the ammonia piping had been accurately modelled.

The achieved accuracy of the laser scanning was 5mm RMSE, providing the client with a high accuracy 3D model of the plant and piping that could be relied upon for precise design.

The terrestrial laser scanning survey achieved an accuracy of 5mm RMSE.

The point cloud and Revit modelling deliverable was hosted on a web-based 3D GIS platform, Pointerra. This allowed project stakeholders to visualize, interrogate and download data without the need for specialist software or powerful computing hardware.