3D Modelling of Rail Bridge

terrestrial laser scanning and Photogrammetry 3D modelling of RAIL bridge for engineering design and condition assessment.

PROJECT OVERVIEW

Bridges in the rail corridor, and the corresponding underdeck, require regular inspection to ensure the integrity of the asset is maintained. Where required, remediation and upgrades to the structure may be required. 3D modelling of rail bridge can help to provide visualisation for condition assessment and a scale accurate model to support engineering design.

To support the condition assessment and detailed design of remediation works, a high detail and high accuracy geospatial survey outputs were required.

Project Scope

DIOSPATIAL SOLUTION

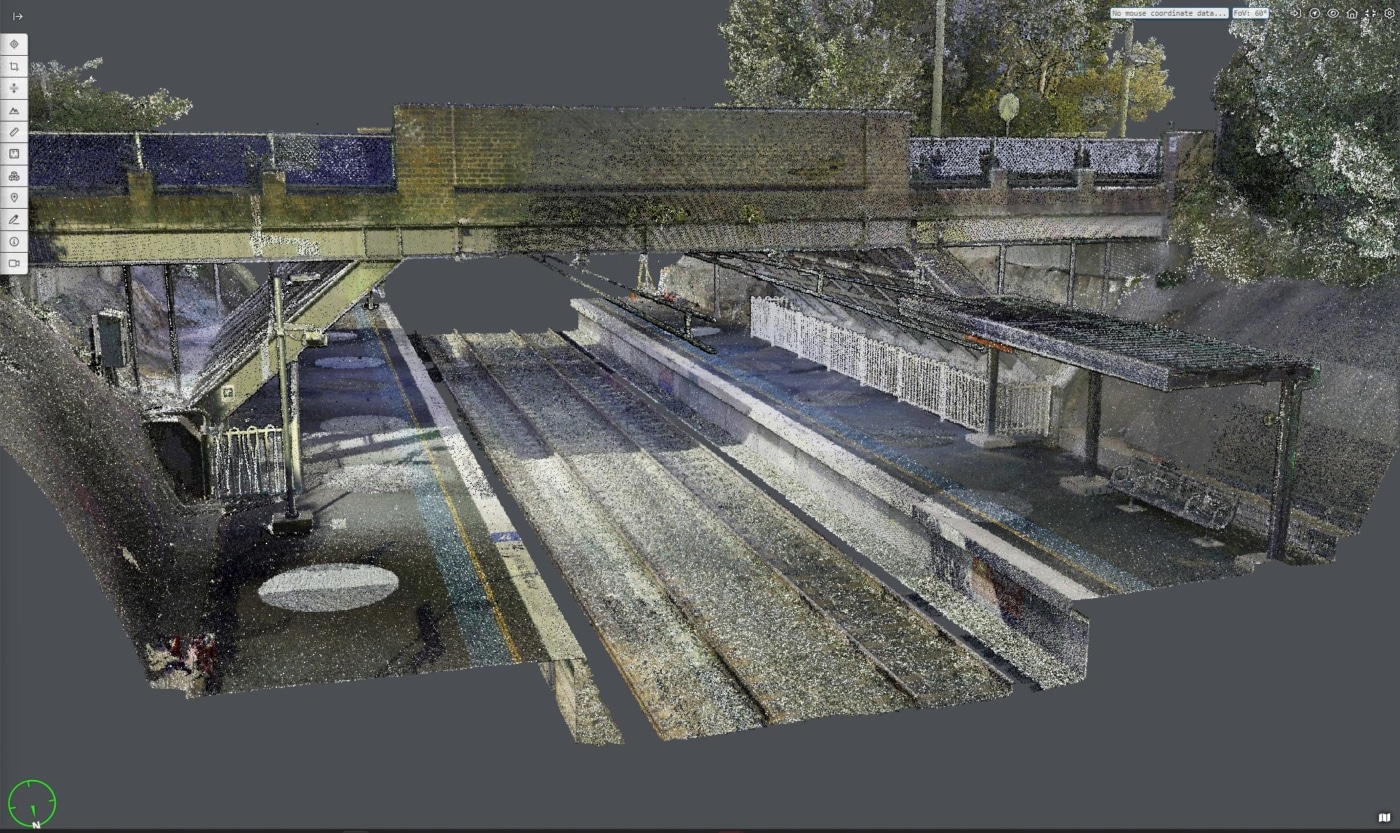

Diospatial developed a reality capture methodology that utilized high resolution imagery and terrestrial laser scanning to produce a high detail, high accuracy 3D modelling of rail bridge.

High resolution imagery was captured from both handheld and drone based methodologies. The imagery and terrestrial laser scanning point cloud were processed in photogrammetry software to produce a 3D textured mesh model. The 3D modelling of rail bridge was both scale and visually accurate which provided rich visualisation of the bridge and surrounding areas. This enabled an accurate remote site inspection and condition assessment by subject matter experts, and significantly optimized communication and stakeholder collaboration.

Terrestrial laser scanning was used for its ability to capture and produce a high accuracy colourised point cloud to complete an accurate 3D survey of the bridge and surrounding areas. This could then be used to support detailed design of upgrades and remediation works. Spherical panoramas were also captured and included in the geospatial data outputs to provide further visualisation. The terrestrial laser scanning point cloud achieved an accuracy of 3mm.

A survey control network was established to check and verify the geolocation and scale of accuracy of all geospatial outputs.

The geospatial outputs were hosted on a web-based 3D GIS platform, Pointerra. This allowed project stakeholders to visualize, interrogate and download data without the need for specialist software or powerful computing hardware. The web-viewer also included ‘click-to-view’ inspection image access, ability to take accurate measurements, annotations and digitizing features with points and polylines.

The reality capture was completed during normal rail operations without the need for possession – minimising disruption to daily rail operations.

All survey works were completed while the trains were running and outside the danger zone, during normal weekday operations. This minimized disruption to daily operations and removed the need for working at heights.

Overall, this 3D modelling of rail bridge solution reduced the need for travel required by the project team and stakeholders, improved safety and minimized disruption to rail operations.